Hello everyone! Welcome to my blog.

Today, I am going to tell you about a rather fascinating piece of engineering and trying my best to explain how it actually works. The machine we are going to cover is the low temperature Stirling engine. The Stirling engine works due to Charles’s law. It is the physical amalgamation of the everlasting and cosmic dance of pressure, volume and temperature, and how they relate to one another.

So how does it work?

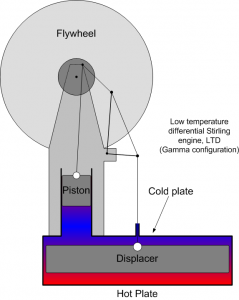

Low temp Stirling engines are special due to, like their name suggests, the temperatures at which they can operate, needing just a small temperature difference between the 2 sides. They consist of 5 main components- container, piston, displacer, flywheel, and an external heat source. (See figure and my engine below)

The engine works in a series of 4 processes: the expansion stage, the power stroke, the contraction phase, and the return stroke.

- Expansion stage- A heat source is placed at the bottom of the Stirling engine. The bottom part of the Stirling engine is often made of metal to allow for greater conductivity of heat. As the gas at the bottom of the engine heats up, the pressure of the gas increases, which pushes the displacer upwards.

- The power stoke- As the displacer moves up, it converts the kinetic energy of the gas (heat) to mechanical work. The movements of the displacer are conveyed to the flywheel and piston, causing them to move. This is the stroke in which power is generated and the flywheel gets the power it needs to rotate during this part of the cycle.

3. The contraction phase- The expanded gas moves to the upper side of the container, which is cooler, causing the air to cool and contract. Similarly, the movement of the displacer above increases the volume of the container in the region where the gas is hot, causing the reduction of gas pressure as Charles’s law dictates (at a constant temperature, volume and pressure are inversely related).

4. The return stroke- As the air below the displacer cools, the pressure on that side of the displacer deceases. Moreover, as the flywheel completes its revolution, its inertia brings the piston down to its original position, deceasing volume` and hence increasing the pressure on the bottom side. The combination of these 2 factors mean that the displacer moves down again, ready to start its cycle once more. In this final phase of the rotation, the flywheel actually inputs power from its motion into the system, which is exactly opposite of what happens in the 2nd phase.

The reason I named the blog “the perpetual motion machine” is because of the fact that your body gives off enough heat to power a low temp stirling engine. If you place the engine in your palms and allow it to heat for a little bit, it will start rotating, giving the illusion of a perpetual motion machine, which is unfortunately not possible in real life.

A few weeks ago, I ordered a Stirling engine from amazon (I’ll leave a link down below for the model I got) and tried running it for the first time. I was honestly surprised at how long it could run for, easily passing the 10 minute mark on the first attempt. I did that by putting the Stirling engine on top of a cup of hot water, allowing the steam to act as the heat source. This is how it looked while operating

Interestingly, according to my research, a Stirling engine should theoretically work with a cold bottom and a hot top too, with the same processes taking place but in different orders. However, when I tried this, it didn’t seem to work. I hypothise that the plastic on the upper side of the stirling engine insulates well and does not let the outside air temperature (which acts like the heat source) create a sufficient temperature difference. I will look into the subject and update the blog incase I find the answer.

This is just the first part of my journey in discovering Stirling engines, and I plan to build one on my own after completely understanding and seeing how it works. (I could’ve done it online too but ordering and doing it with the actual engine is much more fun). Stay tuned for when I actually build it. See you then.

I couldn’t find the exact model but here’s a different although slightly more expensive option👇 https://amzn.eu/d/51A6Bon